What is Stock Control?

A stock control system is basically a database. Stock control is used to show how much stock (physical items) you have at any point in time and how you keep track of it.

Why is Stock Control important

Managing stock effectively is important for any business, because without enough stock, production and sales will grind to a halt. Stock control involves careful planning to ensure that the business has sufficient stock of the right quality available at the right time.

Types of Stock

There are four main types of stock:

- raw materials and components - ready to use in production

- work in progress - stocks of unfinished goods in production

- finished goods ready for sale

- consumables - for example, fuel and stationery

Stock Control Methods

There are several methods for controlling stock, all designed to provide an efficient system for deciding what when and how much to order.

Minimum stock level - you identify a minimum stock level, and re-order when stock reaches

that level. This is known as the just in time method

Stock review - you have regular reviews of stock. At every review you place an

order to return stocks to a predetermined level.

Just In Time (JIT) - this aims to reduce costs by cutting stock to a minimum. Items are

delivered when they are needed for immediate use. This means that less storage

is needed howver there is a risk of running out of stock

Minimum stock level - you identify a minimum stock level, and re-order when stock reaches

that level. This is known as the just in time method

Stock review - you have regular reviews of stock. At every review you place an

order to return stocks to a predetermined level.

Just In Time (JIT) - this aims to reduce costs by cutting stock to a minimum. Items are

delivered when they are needed for immediate use. This means that less storage

is needed howver there is a risk of running out of stock

Data In a Stock Control System

A stock control system is basically a database.

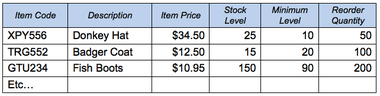

Each record (row) of the database is identified by an item code (the primary key).

Other fields

in each record might include:

Each record (row) of the database is identified by an item code (the primary key).

Other fields

in each record might include:

- Description

- Item price

- Stock level (the number of items held in stock)

- Minimum stock level (when stock falls below this, it needs

to be reordered) - Reorder quantity (how many items one shoud, order each time)

An Example of a Stock Control Database

Recieving New Stock

When items are added in to stock (because a delivery has arrived) this is recorded in the stock control system.

The code of the new items is input to the system (usually using a barcode scanner, or RFID tag). The record for the item is found in the stock

database, or a new record is created, and the stock level is increased.

In many stores, the POS system is directly linked to the stock control system, so that stock levels are adjusted as soon as an item is sold.

The code of the new items is input to the system (usually using a barcode scanner, or RFID tag). The record for the item is found in the stock

database, or a new record is created, and the stock level is increased.

In many stores, the POS system is directly linked to the stock control system, so that stock levels are adjusted as soon as an item is sold.

Advantages

|

Disadvantages

|